2020 has been a crazy year in general for supply chain planners and marks one of the most frustrating and challenging years in recent memory. Constantly producing new challenges that have proven difficult for supply chain managers to navigate and respond to effectively.

Early 2020 saw covid19 take the world by storm resulting in mass factory shutdowns, warehousing disruptions, ocean and air shipping changes adding to an already heavily volatile freight market. March saw freight rates on many domestic lanes skyrocket for a brief amount of time as emergency supplies were being expedited globally. Following this whirlwind, volumes dropped more than any time since the great recession with shippers enjoying some of the lowest domestic freight rates in about a decade. But trucking providers struggling to remain financially viable.

As the world has slowly reopened, and much to the surprise of many analysts, consumer demand has rebounded quickly with many overseas factories revving up production again.

Peak season has been the center of many discussions throughout 2020, with many wondering if there will even be a peak season in 2020. Well over the last couple of months, volumes have hit record highs and rates are at matching records.

Some estimate domestic freight volumes are around 20-25% higher today than in 2018 or 2019, putting significant pressure on US transportation carriers to have capacity for the unexpected volume surge.

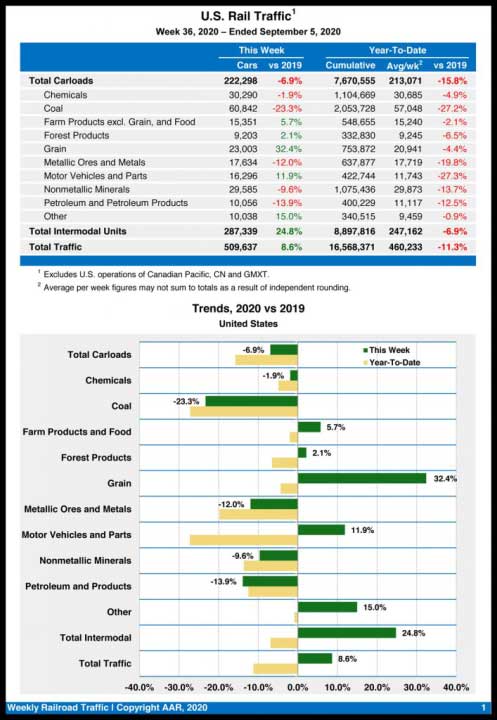

Even rail intermodal experienced a rapid YoY increase of nearly 25% largely attributed to the rapid increase in trucking price and lack of cross-country volume.

Now let’s take a look a why there has been such a surge and how you can best handle peak season.

Why the surge?

The short answer is that the simultaneous rise in consumer demand paired with the delayed freight from earlier in the year have combined to create an immense surge in volume.

In more detail, many importers and even domestic manufacturers curbed production earlier in the year, but in light of demand, spikes have sought to produce as much inventory as possible and have it stocked and available for purchase before the holiday season. Much of this freight would have normally been shipped earlier and spread more evenly throughout the year, however due to covid19, production was delayed and thus hitting the freight ecosystem all at once in a massive wave. According to the Census Bureau, Inventory to sales ratios were extraordinarily low midsummer resulting in firms wanting to restock and rebuild inventory levels.

Trucking capacity has also diminished due to several reasons, but principally increased insurance rates, stricter drug and alcohol testing regulations and covid risks, and low Q2 freight volumes have pushed many drivers and carriers out of the business resulting in a significant shortage of drivers which will continue to for some time.

What should you do?

For shippers, the real question is what should you do. And of course, the answer is “It depends”.

Taking a look at peak season freight solutions means making the assumption that your freight must be delivered in time for the holiday rush.

1. Plan as early as possible

This is without a doubt the most important component of successfully navigating peak season. Work with suppliers, logistics partners and any other stake holders to plan your shipments as early as possible. This means booking ocean freight capacity as soon as the factory has a confirmation on the available date, it means letting domestic logistics partners know when the ship departs and when the freight will be available in the US. This gives your logistics partners several weeks of lead time to prepare asset positioning to best align their service with your volume.

2.Rates are going to be high and highly volatile

We have seen rates increase on certain lanes by around 50% within 10 days, which is extraordinarily hard to deal with for everyone. Proper planning, early booking and diversification strategies can help, but ultimately the freight market is supply and demand based and you should expect to pay much higher rates now that you did even several weeks ago. Keep in mind that you shouldn’t hesitate when it comes to planning shipments even at higher rates, as the absolute most expensive options would be to delay shipment then require air freight to move your inventory or miss out on holiday sales.

3. Diversification

2020 has been the year of diversification for supply chain managers across the world. Coronavirus has shown supply chain planners where the vulnerabilities are in their supply chains and many companies small and large are seeking to diversify their supply and mode base as a hedge against future disruptions. Effectively not wanting to have all their eggs in one basket.

What this means in the long term isn’t fully known as of yet, but expect to see companies spread factory partnerships across multiple countries instead of relying on one, increases in the amount of nearshoring, particularly to Mexico, and build in more tiered processes designed to address disruptions.

In the short term, firms are looking at alternative solutions for freight capacity and spreading their volume across multiple carriers and modes of transportation.

Intermodal has become highly competitive with trucks, many times being 25% or so less expensive on long haul routes and is providing shippers with an all-important safety valve of capacity in markets where trucks are simply unavailable or priced at $3-5 per mile.

Intermodal service has improved on key corridor lanes over the last year or so and represents an attractive alternative for long haul cross country shipping and cross border Mexico shipping. Generally you can expect intermodal transit times to be truck time + 1 day. For many non expedited shipments this is a fair tradeoff and simply results in more free “warehousing” as the products spend more time on a train or in an intermodal yard.

4. Technology

Technology has been adopted quicker in 2020 by supply chain planners than at any point in the last decade. Working from home has necessitated it in many ways, but the rapidly changing logistics market and environment has also favored tech solutions as a way to better plan, manage and analyze freight movements and inventory levels. Better freight visibility gives shippers the ability to more accurate coordinate with dock and warehousing teams, plus provides a heads up if there is a problem. Some logistics technology providers like Zmodal, give shippers access to capacity they wouldn’t otherwise have access to, namely the intermodal network. Being able to quickly find more capacity on a given lane can reduce freight spend and get freight moving now that otherwise might have been delayed until further trucking capacity was available. Inventory and warehouse management systems also give firms an edge when it comes to planning inventory demand and accurately forecasting when replenishments will be needed.

How long will the capacity crunch remain?

This is the tough one, and different analysts are making different predictions, but it’s a safe bet that rates will remain at current levels or even move higher going into the first quarter of 2021. It’s possible that capacity will remain at a deficit for the next 6-8 months which means shippers and their supply chain managers will need to be more resourceful than ever to maintain supply chain operations without breaking the bank.

2020 has been a challenging year for everyone in the supply chain and logistics industry, and navigating peak season is no different!

Stay tuned for more logistics and supply chain updates and tips coming along very soon.

About Zmodal

Zmodal is a digital door to door intermodal provider offering access to the North American intermodal network through our easy to use dashboard, where users can search routes, book, and execute a shipment within a few minutes. Easy shipment tracking, quick payments systems, analytics, and digital documents management make Zmodal the easiest way for shippers to convert freight to intermodal. With 24/7 support and security, you can rest assured your freight is in good hands.

Give us a call or signup today if you want to see how Zmodal can help your supply chain!