Where did the term horsepower come from?!

Horsepower is one of the most ubiquitous terms possible. Nearly every type of engine quotes power figures in horsepower, whether the new Range Rover’s 5.0 supercharged V8, a motorcycle, an electric blower unit on your HVAC, your John Deer lawnmower, case Tractor or GE 4500hp railway locomotive, it’s all quoted in horsepower! Horsepower is without a doubt the most dominant form of power measurement, so much so that the average person would have no understanding of Kwh or other less used forms of power measurement.

But where did this term actually come from?

Well we know it has something to do with horses, but does my 16 horsepower lawnmower really have more power than 16 horses? I’m skeptical.

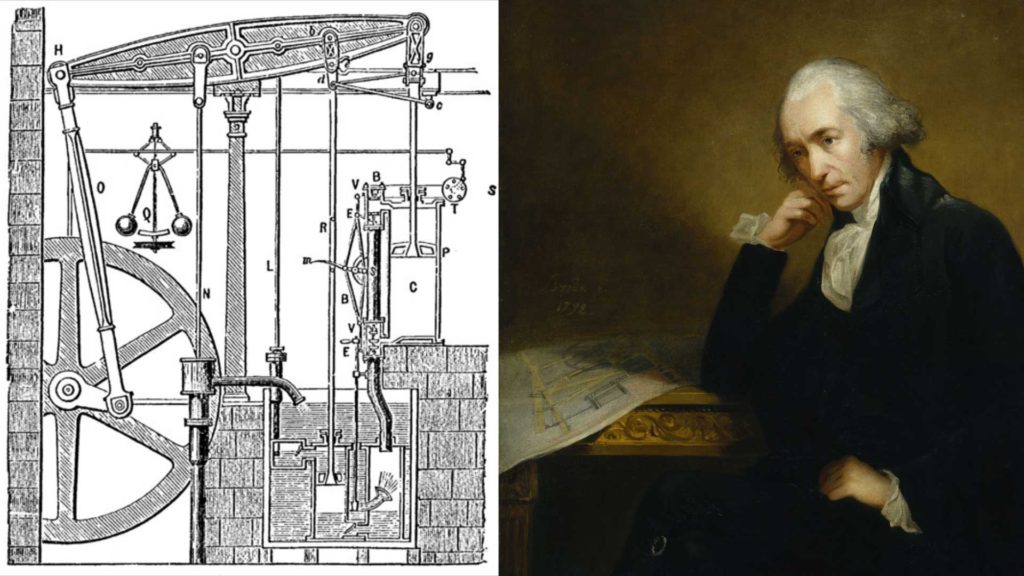

The term originated in the late 1700s as James Watt, an engineer trying to perfect his rudimentary steam engine lacked a way to compare its power output with that of horses. Of course, at this time, there were no cars, internal combustion engines, and even steam engines were in their very very early concept stages, with steam-powered trains still decades away. Horses were the dominant source of power for transportation and water wheels dominated factory power production.

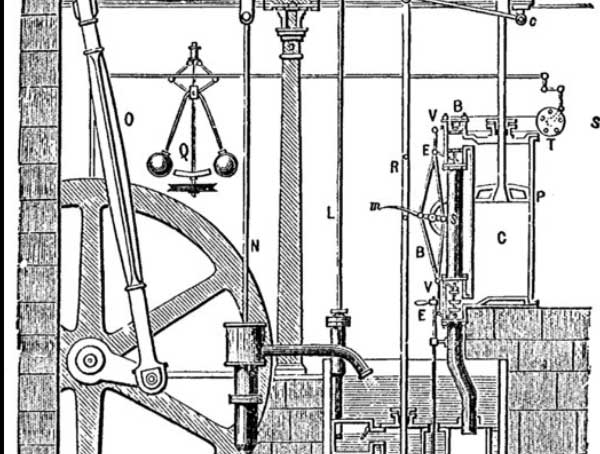

As Watt struggled to convey the power of his new device to would-be buyers, he calculated a draft horse could turn a mill wheel 144 times in an hour and used this along with the speed and radius to calculate the pounds of force the horse was able to generate. In essence, this was how much weight could a horse lift within a period of time using a mill wheel.

The actual rating of horses was for sustained output, as this was most useful for factories. Years later peak output of horses was measured to be around 14-15hp for short durations.

While there are many definitions of horsepower, the most common one, related 1 hp to 33,000 ft-lbs/min. Which then works out to be 746W. This is the basis of mechanical horsepower, in addition to this standard measurement, there is metric horsepower, boiler horsepower, drawbar horsepower. Each then has separate breakdowns as indicated hp, brake hp, and shaft hp. These all are slightly varied calculations based on the application, expectation, and industry standards that have formed over the years.

As steam became the primary source of power behind the industrial revolution, boilers became more and more commonplace in factories and other industrial settings as well as railway locomotives and ships. Boiler horsepower was derived from the original horsepower concept as a way to compare how powerful boilers were. 1 boiler horsepower was defined in 1884 as being the thermal output required to evaporate 34.5 pounds of water at 212 degrees Fahrenheit, being equivalent to 33,469 BTU/hour.

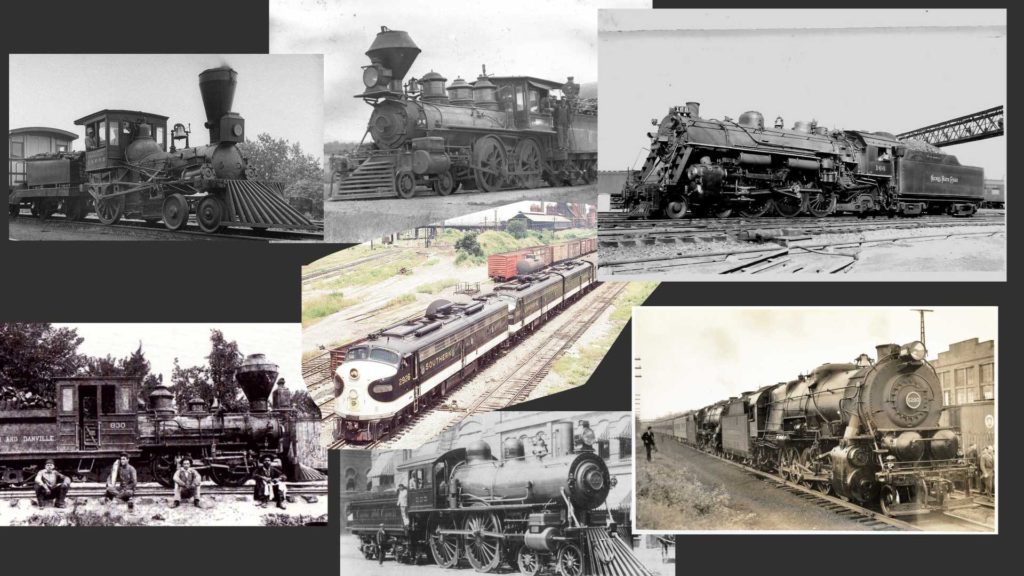

Interestingly enough, horsepower in relation to steam locomotives fell out of favor and the preferred method for measuring the pulling capacity of a locomotive was its tractive effort, which is a measure of essentially how much traction the locomotive can apply to the rails.

A simplified explanation would be that a locomotive can have huge amounts of power, from a large and high-pressure boiler, but will simply spin it’s wheels if it has incorrect weight distribution or is simply too light. Hence using horsepower as a standard of comparison between locomotives could mean that a locomotive with a higher horsepower number will pull much less freight than one with less hp but more TE. Horsepower for railway locomotives is more tied to sustained speed climbing a grade. There were many locomotives that had huge amounts of tractive effort but less boiler horsepower and were only able to travel at lower speeds.

This is a massive simplification as steam locomotives were generally designed for specific tasks, and depending on their called for use, would have different arrangements and sizes of wheels. Since steam locomotives do not have transmission, the drivewheel diameter works like a gear ratio, with large driving wheels permitting high speeds, but less pulling power, while small drive wheels provide more power but less speed. Hence a locomotive built to pull high-speed passenger trains would be designed very differently from a locomotive designed to pull coal trains in the steep hills of West Virginia.

Steam locomotives horsepower and thus sustained speed under load was largely the result of how powerful their boiler was. Meaning how fast and how much water the boiler could turn to steam in any given period of time. As time went on locomotives had ever more advanced boilers designed to increase steam output and efficiency.

For vehicle ratings, including trucks, diesel engines used in ships, trains, and tractors the horsepower rating is the output of the engine itself at the power take-off shaft. This is important to understand as different drivetrains will consume power so that not all of that power actually is available at the wheels.

Generally, a 15-25% drivetrain loss is expected. The type of transmission used, type of clutch, differential, 4WD or 2WD all affect how much loss there is within the driveway.

For the modern supply chain, horsepower has generally maxed out at what is necessary to move freight at the desired weights and speeds with much emphasis currently placed on efficiency. Modern engines can produce the same amount of power as engines from decades ago using much less fuel and producing many fewer emissions.

Truck engines generally produce around 400-600 horsepower, and generate 1000-1200 lb-ft of torque, with some producing nearly 2000lb-ft of torque. Semi trucks utilize many gear ratios for maximizing needed pulling power at a particular speed. Most trucks have at least 12 gears. Overtime semi-trucks have become much more efficient due to mechanical and technological advances. Currently, all-electric trucks are being tested. Likely their first use will be short-haul runs or drayage.

Cargo ships do not have the same size restrictions that trains and trucks have, thus are able to use absolutely massive engines. One of the largest diesel engines ever built generates 109,000hp and is used on a container ship. Many ships have between 20,000 – 80,000 horsepower depending on size, role, and design.

Railway locomotives have continuously evolved as well, from various iterations of steam locomotives to early low horsepower diesel-electric locomotives to hitting 4000+ horsepower in the late 80s. The focus since then has been more on how to get the most “pull” from a set amount of horsepower and energy efficiency. Locomotives originally used analog control systems had rudimentary wheel slip and traction control systems and used DC electric motors to turn the wheels. Modern diesel railway locomotives have highly advanced digital computer control systems to reduce wheel slip, use AC traction motors and thus are able to pull MUCH more weight with the same amount of horsepower.

The US EPA has set guidelines for efficiency for engines across many different industries. Railway locomotives, in particular, must now comply with EPA’s Tier 4B standard which is a struggle for many manufacturers to hit. Use of computer engine control, turbocharging, low friction bearings, exhaust filtration systems, and other technologies are needed to meet these targets while still generating sufficient horsepower as required.

Going forward supply chains will be under increasing pressure to reduce emission and environmental impact at all levels of a supply chain. This along with vehicle regulations will push equipment manufacturers to develop and build increasingly efficient trucks, planes, ships, locomotives, and other machinery. Supply chains also will continue to adopt more efficient modes of transportation such as utilizing intermodal on long haul cross country freight and cross border freight. Intermodal and rail freight are around 75% more energy-efficient than over-the-road trucks, and the adoption of intermodal by supply chains can significantly reduce a supply chain’s environmental impact.

Zmodal is a top intermodal shipping company providing door to door intermodal, and full truckload services nationwide throughout our digital supply chain dashboard which provides easy route searching, booking, document management, and analytics.

Recommended for further reading:

https://www.popularmechanics.com/science/animals/a26074/horsepower-explainer/