With ever-increasing pressure on supply chains to improve cost structure and better optimize their processes, a major focus has been on improving the efficiencies of the inland transportation side of international container shipping.

Inland ports are an important inland transportation link and have grown in popularity with more expected to be built in the next 5 years.

Inland Ports Explained

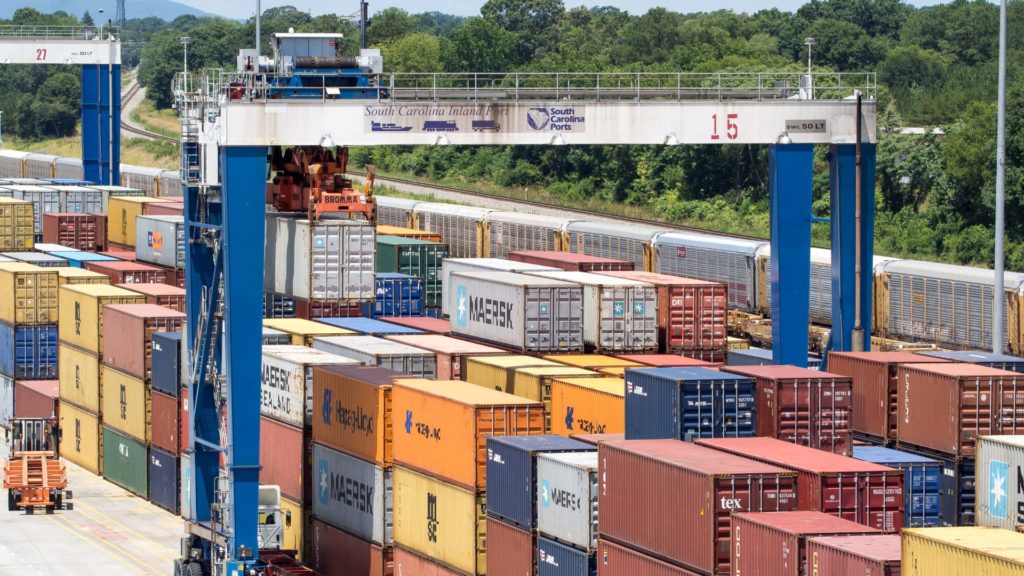

In short, inland ports, mostly what’s referenced in this article are “dry ports”, which provide a means of efficiently moving containers from a ship to an inland location. Many times inland ports are classified as a port of entry, meaning that containers can move the inland location prior to having been cleared by customs. Often inland ports are linked to seaports via rail lines which can handle a huge container volume while keeping hundreds of trucks off of roads linking seaports and inland destinations.

Logistics and supply chain infrastructure typically accompany the port transload center itself, with 3rd party warehousing, distribution centers, repacking, truck terminals, bulk transload facilities, and cold chain services being located within the development. This creates an efficient logistics hub that can cater to a wide variety of different freight types and customer needs.

This not only facilities greener supply chains due to the inherent energy efficiencies of rail intermodal freight, but also means less wear and tear on roadways which reduce the amount of money that municipalities must spend on road maintenance, and also reduces traffic congestion.

The state of Georgia has been a strong proponent of inland ports investing heavily in the inland port north of Atlanta, which allows for shippers receiving international containers to move their freight quickly from the seaport to the inland port via cost-efficient rail service. This keeps supply chain costs down while also keeping hundreds of trucks off the roads through Atlanta.

Neighboring South Carolina, Virginia and North Carolina have also invested and are continuing to invest in more inland port facilities to provide the same type of service that the Georgia inland ports provide.

Inland ports are also unique in how customs laws and tariffs are implemented. In order to quickly move freight out of the seaport, often inland ports allow for customs and tariffs to be dealt with at the inland location which expedites the shipment process and keeps the container yards around the docks more fluid.

As emission regulations tighten over time and road systems become even more congested no doubt the potential ROI for inland ports will only increase and additional inland ports will be planned and built.

Challenges of inland ports

There are a number of challenges that inland ports must face being successful.

Beyond the challenges of finding suitable land, the build costs, and the amount of time that construction projects can take, providing an actual useful facility for shippers is also key to the long-term success of the port.

Keep in mind that drayage trucks must still be used to move the containers from the inland port to the final destination. Drayage capacity can be a challenge depending on the location and volume of the inland port. For example, if the inland port is isolated in the middle of nowhere, it can be hard to find drayage carriers with available capacity, unless the volume of the inland port is enough to sustain carriers, which typically isn’t the case. This problem is less of an issue for inland ports located in larger metropolitan areas as dray trucks should be more readily available.

Railroad service is a key ingredient in the success of facilities. If rail schedules are not time eff

Inland Port Intermodal Pricing

Using the inland port only makes sense if it is cheaper than hiring a drayage carrier for the long move, as hiring a drayage carrier for the full move will be quicker, and for expedited cargo, this will still be the preferred method. The sum of the costs for the rail move to the inland port, the crane fee for unloading the container from the train, and the final mile delivery via drayage truck need to be at a price point that is a discount from the cost of simply draying the container directly. In our opinion, this has been the biggest constraint to the volume growth of inland ports.

Container Availability

Recent frustrations from shippers have been partially due to the lack of availability of empty containers. This is an issue that inland ports face as well, as they seek to maintain a balance between loaded import containers be readily returned to the import facility or ideally being used on a street turn run and loaded with exports. This balance is tough to maintain even for the larger port facilities, hence many us Agriculture exporters facing a tough time moving their products overseas, and many railroads and ocean shipping lines increasing demurrage fees to encourage quicker container turns to address the supply glut.

What does this mean for shippers?

Planning a cost-efficient and reliable supply chain is no easy task for many firms with international supply chains and inland ports are another shipping option that can help increase efficiency and reduce costs. With current freight rates so high with little relief in sight, inland ports and door-to-door intermodal shipping in general offer additional shipping capacity and cost savings.

Ports on both the East and West coasts of the US are heavily congested by ships and containers to the point of causing significant delays and worsening the imbalance of containers and drayage chassis.

Drayage regardless of location is a challenge in the current logistics drayage markets. Drayage from the Port of Savannah, Charleston Drayage, Jacksonville Drayage, and Norfolk drayage are just a few ports that are facing a significant shortage of dray equipment and drivers. This drayage shortage doesn’t seem anywhere near resolving itself.

Increasing the use of inland ports to handle a larger percentage of freight bound for nearby areas to the inland ports will likely increase as it’s a way to keep containers moving more fluidly.

Intermodal Shipping Cost and Capacity 2021

Intermodal shipping both domestic intermodal and international intermodal are powerful sources of additional intermodal capacity and provide a means to move freight when trucking costs are prohibitively high or simply unavailable. Many shippers, particularly small and mid-sized shippers, have yet to implement intermodal trials on their longer lanes. Zmodal makes converting long haul lanes to intermodal, or a portion of long haul freight to domestic door to door intermodal.

Want a free lane and cost savings analysis? – Get in Touch!

Zmodal is a top intermodal shipping company providing door-to-door intermodal, and full truckload services nationwide throughout our digital supply chain dashboard which provides easy route searching, booking, document management, and analytics. CONTACT US if you want to lower your supply chain costs or want access to North American intermodal capacity.

For Further Reading: