Train length and tonnage over the years has increased dramatically.

The push for increased train length is the improved financial and operational efficiency of the railroads. In essence a crew that moves a 30 car trains costs no more than a crew that moves a 300 car train, hence the marginal crew cost changes little as trains increase in tonnage and length. By running fewer much longer trains, crew costs are also reduced. Since the mid 1800s the quest to move more freight per train or ship has pushed engineers to build increasingly large machines as technology allowed.

Railroads move near 40% of gross ton miles domestically in the United States, overwhelming this number is dominated by break bulk commodities. Railroads also provide critical cross border Mexico freight services and freight services between the US and Canada.

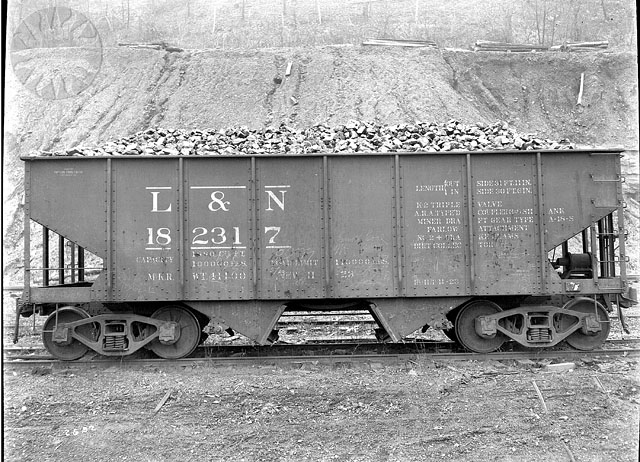

AVERAGE CAR WEIGHT INCREASES

From the 1920s-1970s the average railroad car carried around 50 tons or so of cargo, with the maximum weight of each 4 axle railroad car being 263,000 lbs. Over time, this has increased tremendously to the current standard today of 286K, with some routes being able to tolerate standard 4 axle cars weighing 315,000lbs. This puts around 36 US tons per axle for 286K cars.

As the axle loading increases, the railroad structure itself must be designed to accommodate this extra load, including the rails, bridges, roadbed and any other structures the track is built on.

Typical US railroad rail weighs 141lb/s per yard and is welded to form 2-3 mile long sections of continuous rail which reduces maintenance.

As a comparison in Europe, the standard rail weight is 113lbs/yd with a maximum axle load of around 22 tons. The loading gauge, which is the maximum height and width, of most European railways is also less than that of North American lines.

Overtime this increase in weight permits a train of similar length to carry much more freight. By increasing the weight of each car, overall train capacity is increased dramatically before increasing the length of trains, which allows even more overall train tonnage increase.

Keep in mind over the years railroads have switched entirely from friction bearings to roller bearings which not only reduces rolling friction but also decreases the amount of required maintenance on railcars.

Average length of trains increased

With a continued and renewed focus on increasing operational efficiencies over the last few years, railroads have always sought to move more freight per train. Over the years the average weight of trains cars has risen along with the total length of trains. Locomotive technology in particular has helped to foster this development, with many modern AC diesel electric locomotives being capable of running as “Distributed power”, meaning that a locomotive on the front of a train can radio control another locomotive in the middle of the train, then even a further locomotive on the rear of the train. This allows one train crew to control 6-7 locomotives spread throughout the train which provides a greater deal of control than having all the locomotives on the front of the train and allows for safer train handling.

Long trains also pose some additional challenges for the railroads that operate them. The shear length of some trains are so long that they cannot fit into passing sidings and rail yards at either end, meaning they essentially can “clog up” the rail system. Incredibly long trains take longer to inspect, are more prone to breaking couplers and can be limited as to which routes they operate on. Lots of investment on the part of railroads is required to operate the longer trains, with special attention paid the condition of track, strengthening of bridges. Railroads are also spending hundreds of millions per year to increase siding length which allows trains in opposing directions to pass one another, and increasing the capacity of the rail yards where massive trains originate and terminate.

The longest freight train ever ran in the world was an Australian Ore train that was 7.32km ( 4.5 Miles) long, weighing 99.7K tons. In the United States, the longest train ran was a Norfolk and Western Coal train in West Virginia, totaling 500 cars, 6.5kkm long and weighing 48.1K tons.

For comparison, a fully loaded semi truck weighs at most 40 tons, meaning the record breaking Australian ore train was equivalent to 2493 fully loaded American tractor trailers.

Keep in mind trains of this length are not always practical to run, and thus the upper limit on North American freight trains is generally in the 170-220 car range, totally 14,000 feet or so, with average weights of around 14,000 tons or less. The record breaking trains above were found to be impractical and subsequently weren’t run at this length during normal operation. The average freight train is smaller at a little over a mile, but this average has still increased around 25% since 2008.

The amount of freight moving on North American railroads has risen through the years. The advent of intermodal containerized transportation gave railroads the ability to provide inland point services for steamship lines. In this model international containers are moved from ships onto trains from say the Port of Long Beach, then travel by train to Chicago, in Chicago the containers are loaded onto a truck for the “final mile” to their ultimate destination. Railroads also compete against long haul trucks domestically using intermodal services. Typically these routes are more competitive over 800 miles in length, while shipment time can be a little longer, many times rail intermodal is 10-25% cheaper than over the road trucks which adds up to large shippers. Railroads also move a sizeable percentage of bulk commodities in North America via carload freight and unit trains.

Source: Flickr

Railroads will continue to invest for efficiency improvements with car weight, train weight and length slowly rising over the coming years.

Recommended for Further reading

https://trforum.org/wp-content/uploads/2017/04/2013v52n2_06_HeavyAxleLoads.pdf

https://www.wsj.com/articles/why-railroads-are-making-freight-trains-longer-and-longer-1529055002

http://www.brs.org/index.cfm?zone=/unionactive/view_article.cfm&homeID=768463

https://www.popularmechanics.com/technology/infrastructure/a5314/4345689/

Featured Image Source: Flickr